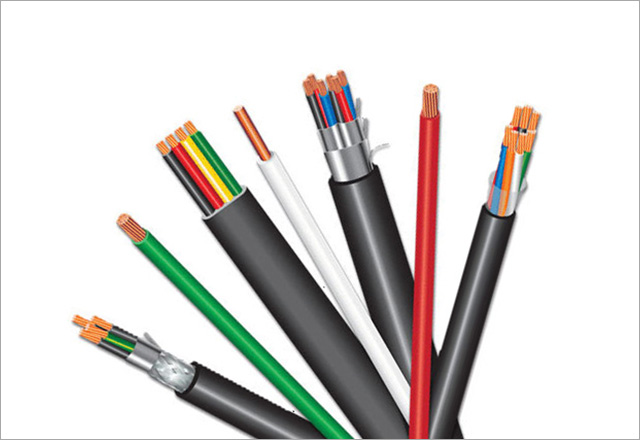

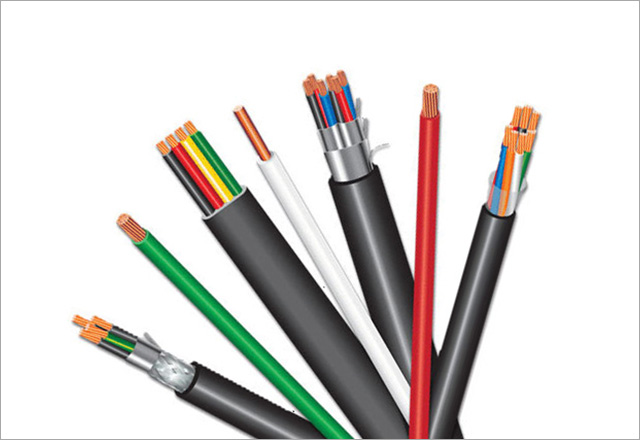

HT and LT Cables

- Higher Electrical Strength Retention

- Higher Short Circuit Rating

- Better Electrical, Mechanical & Thermal Properties

- Easy Jointing & Termination

Selection of Cables

Power Cables are generally selected considering the application. However, following factors are important for selection of suitable cable construction required to transport electrical energy from one end to the other.

- Maximum operating voltage.

- Fault Level.

- Load to be carried.

- Possible overloading duration & magnitude.

- Route length and voltage drop.

- Mode of installation considering installation environment such as ambient & ground

temperature chemical & physical properties of soil.

- Flame retardant properties.

All sizes of XLPE cables are designed to standard operating conditions in India and abroad. The standards adopted are considering the geographical/climatical conditions and general applications of power for utilities, distribution and generation purposes.

The cables are manufactured conforming to Indian & International cables specifications for XLPE Insulated cables. Customer specific requirements can also be met.

Guidelines for selection of Cables:-

- Voltage Grade: 1.9 / 3.3 kV (E), 3.3 / 3.3 kV (UE), 3.8 / 6.6 kV (E) , 6.6 / 6.6 kV (UE), 6.35 / 11 kV (E), 11 / 11 kV (UE), 12.7 / 22 kV (E) & 33 kV (E), 33 kV (UE) , 45 kV & 66kV

- Relevant Indian Standard: IS 7098 (Part-2) – 1985 or International standard – IEC-60502 (Part-2), BS-6622 & BS:7835.

- Number of cores: Single & Three.

- Conductor: Size – 35 Sq.mm to 1000 Sq.mm in Single Core Cables & 35 Sq.mm to 400 Sq.mm in 3 Core cables.

- Conductor Material: Copper / Aluminium

- Type of Insulation: XLPE

- Type of Inner Sheathing: PVC Wrapped / PVC Extruded.

- Type of Armour: Unarmoured / Strip Armoured / Round Wire Armoured.

- Type of Outer Sheath: PVC / Flame Retardant / Flame Retardant Low Smoke / Zero Halogen (LSOH).

- Length of cable required and drum length.

Note: Detailed Leaflet for 66kV & above can be available on specific request.

LP XLPE Cables:

Advantages of XLPE Cables -

- L.V. PVC & XLPE Power Cables With Copper Ano Aluminium Conductor

- L.V. PVC & XLPE Control Cables With Copper Conductor

- M.V. Power Cables Upto 33 Kv

- EHV Cables From 66kv To 220kv

- M.V. / L.V. Aerial Bunched Cables (ABC)

- Zero Halogen Cables

- Fire Survival Cables (FS)

- Instrumentation Cables Screened/Unscreened

- Industrial Braided Cables

- Thermo Couple / Compensating Cables

- Lead Sheathed Cables

- Rubber Cables

- Railway Signalling Cables

- Telephone Cables Dry & Jelly Filled

- Building Wires FR / FRLS / FRZH / FRLF / FRFS

- Single Core Industrial Flexibles PVC / FR / FRLS / FRZH / HRFR / HR / HR-FRLS / FRLF / FRFS

- Multi Core Industrial Flexible Cables

- Submersible Flat And Round Cables

- Coaxial Cables

- LAN CAT-5E/ CAT 6 Cables

- Welding Cables

- Solar AC / DC Cables

- Steel Braided Cables

- Speciality Cables Suited For Marine / OIL 8. GAS / Extreme Fire Conditions / Highly Corrosive Environment / Traffic / Aircraft / Space Station / Automobiles

- Optic Fibre Cables

Commercial Advantages:

- Lower laying cost because of comparatively smaller diameter of cable and higher weight*.

- Lower installation charges as the diameter of cable is comparatively lesser with smaller bending radius, requiring less space requirement for laying cables.

- **One size lower cable can be used as compared to PVC insulated cable.

Advantages of XLPE Cables –

- Higher Electrical Strenght Retention

- Higher Short Circuit Rating

- Better Electrical, Mechanical & Thermal Properties

- Easy Joining & Termination

Power Cables are generally selected considering the application. However following factors are important for selection of suitable cable construction required to transport electrical energy form one end to the other.

- Maximum operating voltage.

- Fault level..

- Load to be carried..

- Possible overloading during & magnitude..

- Route length and voltage drop..

- Mode of installation considering installation environment such as ambient & ground temperature as well as chemical & physical properties of soil..

- Flame retardant properties..

All sizes of XLPE cables are designed for standard operating conditions in India and abroad. The standards adopted are after duly considering the geographical I climatical conditions and general applications of powerfor utilities, distribution and generation purposes. The cables are manufactured conforming to Indian & International cables specification for XLPE Insulated cables. Customer specific requirements can also be met.